Introduction

Chairs are an essential part of everyday life, and they come in a variety of materials. One of the most popular materials used to make chairs is thermosetting plastics. Thermosetting plastics are a type of plastic that is heat-resistant and durable, making them ideal for furniture. They are also lightweight, easy to clean, and can be molded into a variety of shapes and sizes. Additionally, thermosetting plastics are cost-effective and can be used to create a wide range of designs. This makes them a great choice for chairs, as they can be used to create comfortable and stylish seating solutions.

The Benefits of Thermosetting Plastics for Chair Manufacturing

Thermosetting plastics are a popular choice for chair manufacturing due to their many benefits. These plastics are highly durable and resistant to wear and tear, making them ideal for chairs that will be used frequently. They are also resistant to heat, moisture, and chemicals, making them suitable for outdoor use. Additionally, thermosetting plastics are lightweight and easy to work with, making them a cost-effective choice for chair manufacturing.

Thermosetting plastics are also highly customizable, allowing manufacturers to create chairs with unique shapes and designs. This makes them a great choice for chairs that need to fit into a specific space or have a certain aesthetic. Furthermore, thermosetting plastics are available in a variety of colors and finishes, allowing manufacturers to create chairs that match any décor.

Finally, thermosetting plastics are environmentally friendly. They are made from renewable resources and can be recycled, making them a sustainable choice for chair manufacturing. Additionally, thermosetting plastics are non-toxic and do not emit any harmful fumes, making them safe for both the environment and the people who use the chairs.

Overall, thermosetting plastics are an excellent choice for chair manufacturing due to their durability, versatility, and environmental friendliness. They are a cost-effective and sustainable option that can be used to create chairs of any shape, size, and color.

Exploring the Durability of Thermosetting Plastics for Chair Design

Thermosetting plastics are a type of plastic that are widely used in the design of chairs due to their durability and strength. These plastics are formed by the chemical reaction of a resin and a curing agent, which creates a strong and rigid material that is resistant to heat, chemicals, and other environmental factors.

The durability of thermosetting plastics makes them an ideal material for chair design. These plastics are highly resistant to wear and tear, and they can withstand extreme temperatures and harsh chemicals. This makes them an excellent choice for outdoor furniture, as they can withstand the elements without deteriorating. Additionally, thermosetting plastics are lightweight and easy to work with, making them a great choice for furniture designers.

Thermosetting plastics are also highly resistant to cracking and breaking. This makes them an ideal material for chairs that are designed to be used in high-traffic areas, such as restaurants and offices. The strength of these plastics also makes them a great choice for chairs that are designed to support heavy loads, such as those used in medical facilities.

Finally, thermosetting plastics are also highly resistant to fading and discoloration. This makes them an excellent choice for chairs that are designed to be used in areas with direct sunlight, such as patios and decks. The color of these plastics will remain vibrant and true for many years, making them a great choice for furniture designers who want to create pieces that will last for years to come.

Overall, thermosetting plastics are an excellent choice for chair design due to their durability and strength. These plastics are highly resistant to wear and tear, cracking, and fading, making them an ideal material for furniture designers who want to create pieces that will last for years to come.

The Advantages of Thermosetting Plastics for Chair Comfort

Thermosetting plastics are a type of plastic that is widely used in the production of chairs for comfort and durability. These plastics are formed by the application of heat and pressure, and they are known for their superior strength and resistance to wear and tear. As such, they are an ideal material for chairs that are designed to provide comfort and support for long periods of time.

One of the primary advantages of thermosetting plastics for chair comfort is their ability to provide superior support. These plastics are designed to be flexible and resilient, allowing them to conform to the shape of the user’s body and provide a comfortable seating experience. This flexibility also helps to reduce the amount of pressure that is placed on the user’s body, which can help to reduce fatigue and discomfort.

Another advantage of thermosetting plastics for chair comfort is their durability. These plastics are designed to withstand the wear and tear of everyday use, making them an ideal choice for chairs that are used frequently. This durability also helps to ensure that the chair will remain comfortable and supportive for a long period of time.

Finally, thermosetting plastics are also known for their resistance to heat and moisture. This makes them an ideal choice for chairs that are used in areas where there is a high level of humidity or temperature. This resistance helps to ensure that the chair will remain comfortable and supportive even in extreme conditions.

Overall, thermosetting plastics are an ideal choice for chairs that are designed to provide comfort and support. These plastics are designed to be flexible and resilient, allowing them to conform to the shape of the user’s body and provide a comfortable seating experience. They are also known for their durability and resistance to heat and moisture, making them an ideal choice for chairs that are used in areas where there is a high level of humidity or temperature. As such, thermosetting plastics are an excellent choice for chairs that are designed to provide comfort and support for long periods of time.

How Thermosetting Plastics Enhance Chair Aesthetics

Thermosetting plastics are a type of plastic that is used to enhance the aesthetics of chairs. These plastics are known for their durability and strength, making them ideal for use in furniture. They are also resistant to heat, chemicals, and other environmental factors, making them a great choice for outdoor furniture.

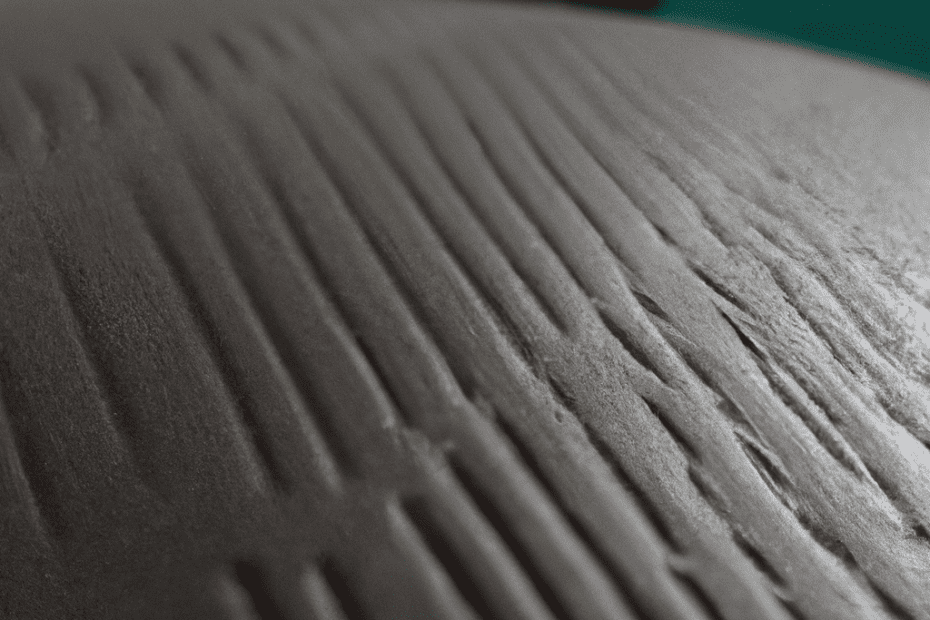

Thermosetting plastics are available in a variety of colors and textures, allowing for a wide range of design options. They can be molded into any shape, allowing for a unique look that can be tailored to the individual’s taste. The plastic can also be textured to create a unique look and feel.

Thermosetting plastics are also lightweight, making them easy to move and transport. This makes them ideal for use in chairs that need to be moved around frequently. The plastic is also resistant to scratches and dents, making it a great choice for chairs that will be used in high-traffic areas.

Thermosetting plastics are also easy to clean and maintain. The plastic is non-porous, meaning it won’t absorb dirt or other debris. This makes it easy to keep the chair looking its best.

Overall, thermosetting plastics are an excellent choice for enhancing the aesthetics of chairs. They are durable, lightweight, and easy to maintain, making them a great choice for any type of chair.

The Cost-Effectiveness of Thermosetting Plastics for Chair Manufacturing

Thermosetting plastics are a cost-effective material for chair manufacturing. This type of plastic is a polymer that is heated and then cooled to form a solid, durable material. It is a popular choice for furniture production due to its low cost, durability, and ease of use.

Thermosetting plastics are a cost-effective material for chair manufacturing because they are relatively inexpensive compared to other materials. The cost of the raw material is low, and the production process is simple and efficient. This makes it an ideal choice for mass production of chairs. Additionally, thermosetting plastics are highly durable and resistant to wear and tear. This makes them a great choice for chairs that will be used in high-traffic areas or for chairs that will be used for a long period of time.

Thermosetting plastics are also easy to use in the manufacturing process. The material can be easily molded into the desired shape and size, and it can be painted or finished with a variety of colors and textures. This makes it a great choice for customizing chairs to meet the needs of a particular customer. Additionally, thermosetting plastics are lightweight, making them easy to transport and store.

Overall, thermosetting plastics are a cost-effective material for chair manufacturing. They are inexpensive, durable, and easy to use, making them an ideal choice for mass production of chairs. Additionally, they are lightweight and can be customized to meet the needs of a particular customer. For these reasons, thermosetting plastics are a great choice for chair manufacturing.

The Versatility of Thermosetting Plastics for Chair Design

Thermosetting plastics are a versatile material for chair design, offering a range of benefits that make them an ideal choice for furniture makers. These plastics are strong and durable, making them suitable for a variety of applications. They are also lightweight, making them easy to transport and install. Additionally, thermosetting plastics are resistant to corrosion, making them a great choice for outdoor furniture.

Thermosetting plastics are also highly customizable, allowing furniture makers to create unique designs that meet their specific needs. These plastics can be molded into a variety of shapes and sizes, allowing for a wide range of design possibilities. Additionally, thermosetting plastics can be colored and textured to create a unique look and feel. This makes them an ideal choice for creating chairs that stand out from the crowd.

Thermosetting plastics are also cost-effective, making them a great choice for budget-conscious furniture makers. These plastics are relatively inexpensive compared to other materials, making them a great option for those looking to save money. Additionally, thermosetting plastics are easy to work with, making them a great choice for those who are new to furniture making.

Overall, thermosetting plastics are a great choice for chair design. They are strong and durable, lightweight, corrosion-resistant, customizable, and cost-effective. These qualities make them an ideal choice for furniture makers looking to create unique and stylish chairs.

The Environmental Impact of Thermosetting Plastics for Chair Manufacturing

Thermosetting plastics are a popular material used in the manufacturing of chairs. While they offer a range of benefits, such as durability and cost-effectiveness, their use also has an environmental impact.

Thermosetting plastics are made from a combination of synthetic polymers, such as polyurethane, and natural materials, such as wood. The production of these materials requires the use of energy and resources, which can have a negative impact on the environment. For example, the production of polyurethane requires the use of petroleum-based chemicals, which can release volatile organic compounds (VOCs) into the atmosphere. VOCs are known to contribute to air pollution and can have a negative effect on human health.

The manufacturing process of thermosetting plastics also produces a range of hazardous waste materials, such as solvents and heavy metals. These materials can be difficult to dispose of safely and can have a detrimental effect on the environment if not managed correctly.

The use of thermosetting plastics in chair manufacturing can also have an impact on the environment through the use of adhesives. Adhesives are often used to bond the plastic to other materials, such as wood or metal. These adhesives can contain hazardous chemicals, such as formaldehyde, which can be released into the atmosphere during the manufacturing process.

Finally, thermosetting plastics are not biodegradable, meaning that they can remain in the environment for a long time after they have been discarded. This can lead to the accumulation of plastic waste in landfills, which can have a negative impact on the environment.

In conclusion, while thermosetting plastics offer a range of benefits for chair manufacturing, their use also has an environmental impact. It is important to be aware of the potential environmental impacts of using thermosetting plastics and to take steps to reduce their impact. This can include using more sustainable materials, such as recycled plastics, and ensuring that hazardous waste materials are disposed of safely.

The Safety Benefits of Thermosetting Plastics for Chair Design

Thermosetting plastics are a type of plastic material that is becoming increasingly popular for use in chair design. This material offers a number of safety benefits that make it an ideal choice for chairs, particularly those that are used in public spaces.

One of the primary safety benefits of thermosetting plastics is their durability. This material is highly resistant to wear and tear, meaning that it can withstand heavy use without becoming damaged or worn down. This makes it an ideal choice for chairs that are used in public spaces, as they will be able to withstand the rigors of daily use without becoming damaged or unsafe.

Thermosetting plastics are also highly resistant to fire. This makes them an ideal choice for chairs that are used in public spaces, as they will not easily catch fire and spread the flames to other areas. This is particularly important in areas where there is a risk of fire, such as restaurants and other public spaces.

Thermosetting plastics are also highly resistant to chemicals. This makes them an ideal choice for chairs that are used in areas where there is a risk of chemical exposure, such as laboratories and medical facilities. The material is also resistant to corrosion, meaning that it will not easily become damaged by exposure to water or other liquids.

Finally, thermosetting plastics are also highly resistant to UV radiation. This makes them an ideal choice for chairs that are used outdoors, as they will not easily become damaged by exposure to the sun’s rays. This is particularly important for chairs that are used in areas where there is a risk of sun exposure, such as parks and beaches.

Overall, thermosetting plastics offer a number of safety benefits that make them an ideal choice for chair design. This material is highly durable, resistant to fire, chemicals, and UV radiation, making it an ideal choice for chairs that are used in public spaces.

The Impact of Thermosetting Plastics on Chair Maintenance

Thermosetting plastics have had a significant impact on chair maintenance. This type of plastic is a polymer that is heated and then cooled to form a solid, durable material. It is often used to make furniture, such as chairs, due to its strength and durability.

Thermosetting plastics are resistant to wear and tear, making them ideal for chair maintenance. They are also resistant to water, heat, and chemicals, which makes them ideal for use in outdoor furniture. This type of plastic is also resistant to scratches and dents, which can be a major issue with other materials.

Thermosetting plastics are also easy to clean and maintain. They can be wiped down with a damp cloth and mild detergent, and they can also be polished with a soft cloth. This makes them ideal for use in areas where frequent cleaning is necessary, such as restaurants and other public spaces.

Thermosetting plastics are also lightweight, making them easy to move and transport. This makes them ideal for use in areas where furniture needs to be moved frequently, such as in offices or classrooms.

Overall, thermosetting plastics have had a significant impact on chair maintenance. They are durable, easy to clean and maintain, and lightweight, making them ideal for use in a variety of settings. As a result, they have become a popular choice for furniture makers and consumers alike.

Exploring the Future of Thermosetting Plastics for Chair Manufacturing

Thermosetting plastics are a type of plastic that is widely used in the manufacturing of chairs. This type of plastic is known for its durability and strength, making it an ideal material for chair production. As technology advances, the use of thermosetting plastics in chair manufacturing is likely to become even more widespread.

Thermosetting plastics are created by combining two or more polymers with a curing agent. This process creates a strong, durable material that is resistant to heat, chemicals, and other environmental factors. The material is also lightweight, making it easy to transport and assemble.

The use of thermosetting plastics in chair manufacturing has several advantages. For one, the material is highly durable and can withstand a great deal of wear and tear. Additionally, the material is resistant to corrosion and other environmental factors, making it ideal for outdoor use. Furthermore, thermosetting plastics are relatively inexpensive, making them a cost-effective option for chair production.

In the future, thermosetting plastics are likely to become even more widely used in chair manufacturing. As technology advances, the material is likely to become even more durable and lightweight. Additionally, the material is likely to become more cost-effective, making it an even more attractive option for chair production.

The use of thermosetting plastics in chair manufacturing is likely to continue to grow in the future. This type of plastic is highly durable, lightweight, and cost-effective, making it an ideal material for chair production. As technology advances, the use of thermosetting plastics is likely to become even more widespread, making it an even more attractive option for chair production.

Q&A

1. What is thermosetting plastic?

Thermosetting plastic is a type of plastic that is heat-resistant and durable. It is made from a combination of synthetic resins and other materials, such as glass fibers, and is used to make a variety of products, including chairs.

2. Why are chairs made of thermosetting plastics?

Chairs made of thermosetting plastics are strong and durable, making them ideal for use in a variety of settings. They are also resistant to heat, making them suitable for use in areas where temperatures may fluctuate. Additionally, thermosetting plastics are lightweight, making them easy to move and transport.

3. What are the advantages of using thermosetting plastics for chairs?

Thermosetting plastics are strong and durable, making them ideal for use in a variety of settings. They are also resistant to heat, making them suitable for use in areas where temperatures may fluctuate. Additionally, thermosetting plastics are lightweight, making them easy to move and transport.

4. Are there any disadvantages to using thermosetting plastics for chairs?

Thermosetting plastics are not as flexible as other materials, such as wood, and may not be as comfortable to sit on. Additionally, thermosetting plastics are not as aesthetically pleasing as other materials, such as wood or metal.

5. How long do chairs made of thermosetting plastics last?

Chairs made of thermosetting plastics can last for many years if they are properly cared for.

6. Are chairs made of thermosetting plastics recyclable?

Yes, chairs made of thermosetting plastics can be recycled.

7. Are chairs made of thermosetting plastics fire-resistant?

Yes, chairs made of thermosetting plastics are fire-resistant.

8. Are chairs made of thermosetting plastics waterproof?

No, chairs made of thermosetting plastics are not waterproof.

9. Are chairs made of thermosetting plastics easy to clean?

Yes, chairs made of thermosetting plastics are easy to clean with mild soap and water.

10. Are chairs made of thermosetting plastics environmentally friendly?

Yes, chairs made of thermosetting plastics are generally considered to be environmentally friendly because they are recyclable and do not contain any hazardous materials.

Conclusion

Chairs made of thermosetting plastics are ideal for a variety of applications due to their durability, strength, and resistance to heat and chemicals. They are also lightweight and easy to clean, making them a great choice for both indoor and outdoor use. Additionally, thermosetting plastics are cost-effective and can be molded into a variety of shapes and sizes, making them a great choice for any seating needs.

- where are chairs made - May 26, 2024

- how much are metal chairs - May 25, 2024

- how to distress metal chairs - May 25, 2024