Introduction

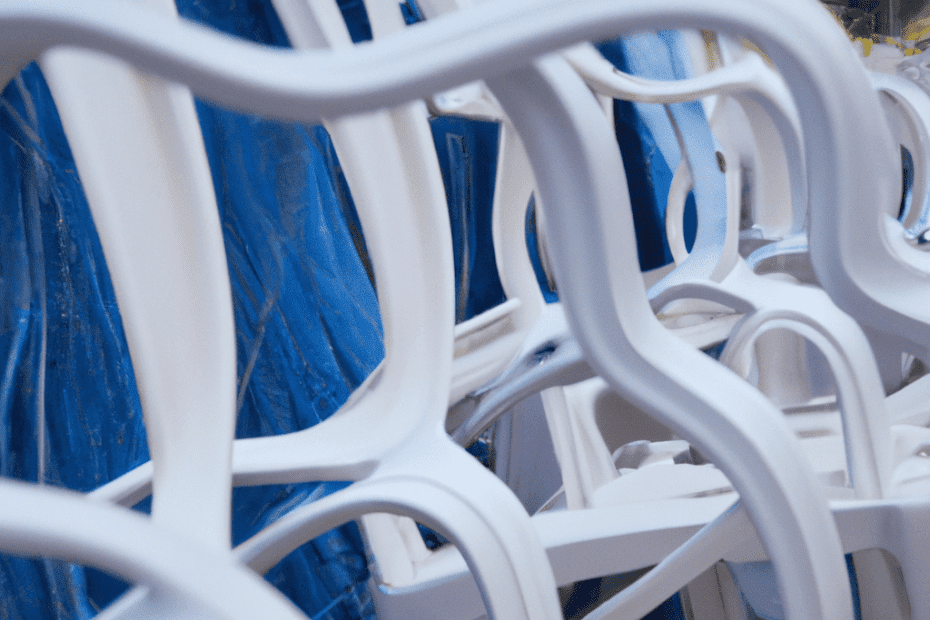

Plastic chairs are a popular choice for many homes and businesses due to their affordability, durability, and versatility. The manufacturing process for plastic chairs is a complex one, involving a variety of steps and materials. The process begins with the selection of the plastic material, which is then heated and molded into the desired shape. The chair is then cooled and trimmed to the desired size and shape. Finally, the chair is painted and finished with a protective coating. The end result is a sturdy, attractive, and long-lasting plastic chair.

The Different Types of Plastic Used to Manufacture Plastic Chairs

Plastic chairs are a popular choice for both indoor and outdoor seating due to their affordability, durability, and versatility. Plastic chairs come in a variety of styles and colors, and are made from a variety of different types of plastic. Understanding the different types of plastic used to manufacture plastic chairs can help you make an informed decision when selecting the right chair for your needs.

The most common type of plastic used to manufacture plastic chairs is polypropylene. This type of plastic is lightweight, durable, and resistant to moisture, making it an ideal choice for outdoor seating. Polypropylene is also easy to clean and maintain, making it a popular choice for both residential and commercial use.

Another type of plastic used to manufacture plastic chairs is polyethylene. This type of plastic is more flexible than polypropylene, making it a great choice for chairs that require more flexibility. Polyethylene is also resistant to moisture and is easy to clean and maintain.

A third type of plastic used to manufacture plastic chairs is polyvinyl chloride (PVC). PVC is a strong and durable plastic that is resistant to moisture and chemicals. It is also easy to clean and maintain, making it a popular choice for both indoor and outdoor seating.

Finally, ABS plastic is another type of plastic used to manufacture plastic chairs. ABS plastic is a strong and durable plastic that is resistant to moisture and chemicals. It is also easy to clean and maintain, making it a popular choice for both indoor and outdoor seating.

No matter which type of plastic you choose for your plastic chairs, it is important to remember that all plastics have their own unique properties and benefits. Understanding the different types of plastic used to manufacture plastic chairs can help you make an informed decision when selecting the right chair for your needs.

The Benefits of Using Plastic to Manufacture Chairs

Plastic is a versatile material that is widely used in the manufacture of chairs. It offers a number of advantages over other materials, making it an ideal choice for many applications.

One of the primary benefits of using plastic to manufacture chairs is its durability. Plastic is highly resistant to wear and tear, making it an ideal choice for chairs that will be used frequently. It is also resistant to moisture, making it suitable for outdoor use. Additionally, plastic is lightweight, making it easy to move and transport.

Another advantage of using plastic to manufacture chairs is its affordability. Plastic is a relatively inexpensive material, making it a cost-effective choice for many applications. Additionally, plastic is easy to work with, allowing manufacturers to produce chairs quickly and efficiently.

The versatility of plastic is also a major benefit. Plastic can be molded into a variety of shapes and sizes, allowing manufacturers to create chairs in a wide range of styles and designs. Additionally, plastic can be colored or textured to create a unique look.

Finally, plastic is an environmentally friendly material. It is non-toxic and recyclable, making it a sustainable choice for many applications. Additionally, plastic does not require the use of harsh chemicals or solvents during the manufacturing process, making it a safe choice for both the environment and the people who use the chairs.

In conclusion, plastic is an ideal material for the manufacture of chairs. It is durable, affordable, versatile, and environmentally friendly, making it an excellent choice for many applications.

The Process of Injection Molding for Plastic Chair Manufacturing

Injection molding is a process used for the mass production of plastic chairs. It is a manufacturing technique that involves injecting molten plastic into a mold to form the desired shape. The process is highly efficient and cost-effective, making it a popular choice for many plastic chair manufacturers.

The injection molding process begins with the creation of a mold. This mold is typically made from metal and is designed to the exact specifications of the desired chair. Once the mold is created, it is placed into an injection molding machine. The machine then heats the plastic material to a molten state and injects it into the mold. The molten plastic is then cooled and solidified, forming the chair.

The injection molding process is highly automated and requires minimal human intervention. The machine is programmed to control the temperature, pressure, and speed of the injection process. This ensures that the plastic is injected into the mold with precision and accuracy.

Once the plastic has been injected into the mold, it is removed and the chair is ready for assembly. The chair is then inspected for quality and any defects are corrected. The chair is then packaged and shipped to the customer.

Injection molding is a highly efficient and cost-effective process for producing plastic chairs. It is a reliable and repeatable process that produces consistent results. The process is also highly automated, making it a popular choice for many plastic chair manufacturers.

The Advantages of Automated Plastic Chair Manufacturing

Automated plastic chair manufacturing is a process that has revolutionized the furniture industry. This process has numerous advantages that make it a preferred choice for many businesses.

The first advantage of automated plastic chair manufacturing is its cost-effectiveness. Automated manufacturing processes are more efficient than manual processes, which means that businesses can produce more chairs in less time and with fewer resources. This leads to lower production costs, which can be passed on to the consumer in the form of lower prices. Additionally, automated processes require less labor, which can help businesses save on labor costs.

The second advantage of automated plastic chair manufacturing is its speed. Automated processes are much faster than manual processes, which means that businesses can produce more chairs in a shorter amount of time. This can help businesses meet customer demand more quickly and efficiently.

The third advantage of automated plastic chair manufacturing is its accuracy. Automated processes are more precise than manual processes, which means that businesses can produce chairs with fewer defects. This can help businesses maintain a higher level of quality control and ensure that their products meet customer expectations.

Finally, automated plastic chair manufacturing is more environmentally friendly than manual processes. Automated processes require fewer resources and generate less waste, which can help businesses reduce their environmental impact. Additionally, automated processes can help businesses reduce their energy consumption, which can help them save money and reduce their carbon footprint.

Overall, automated plastic chair manufacturing is a process that has numerous advantages. It is cost-effective, fast, accurate, and environmentally friendly, which makes it a preferred choice for many businesses.

The Challenges of Manufacturing Plastic Chairs

Manufacturing plastic chairs is a challenging process that requires a great deal of skill and precision. The process involves a number of steps, from the initial design and molding of the chair to the final assembly and finishing. Each step must be carefully executed in order to ensure the highest quality product.

The first step in the process is the design and molding of the chair. This involves creating a prototype of the chair and then creating a mold from which the plastic chair can be formed. The mold must be designed to exact specifications in order to ensure that the chair is structurally sound and aesthetically pleasing. The mold must also be able to withstand the high temperatures and pressures of the injection molding process.

Once the mold is created, the plastic material must be prepared for injection molding. This involves heating the plastic to a specific temperature and then injecting it into the mold. The plastic must be heated to the correct temperature in order to ensure that it flows properly and fills the mold completely.

Once the plastic has been injected into the mold, it must be cooled and then removed from the mold. This is a delicate process that requires great care in order to ensure that the plastic does not warp or crack. Once the plastic has been removed from the mold, it must be trimmed and finished. This involves sanding, painting, and other finishing touches that will give the chair its final look.

Finally, the chair must be assembled. This involves attaching the legs, arms, and other components to the chair. This is a complex process that requires a great deal of skill and precision in order to ensure that the chair is structurally sound and aesthetically pleasing.

Manufacturing plastic chairs is a challenging process that requires a great deal of skill and precision. Each step of the process must be carefully executed in order to ensure the highest quality product. With the right tools and expertise, however, it is possible to create a beautiful and durable plastic chair.

The Impact of Recycled Plastic on Plastic Chair Manufacturing

The use of recycled plastic in the manufacturing of plastic chairs has become increasingly popular in recent years. This is due to the fact that recycled plastic is a more sustainable and cost-effective option than traditional plastic. As such, it has the potential to significantly reduce the environmental impact of plastic chair production.

Recycled plastic is made from post-consumer plastic waste, such as plastic bottles, containers, and packaging. This material is collected, sorted, and processed into pellets or flakes, which can then be used to create new products. The use of recycled plastic in the production of plastic chairs has several advantages.

First, it reduces the amount of plastic waste that is sent to landfills. By using recycled plastic, manufacturers can reduce their reliance on virgin plastic, which is derived from petroleum and other non-renewable resources. This helps to conserve natural resources and reduce the amount of pollution associated with the production of plastic.

Second, recycled plastic is often cheaper than virgin plastic. This is because it does not require the same level of processing and energy consumption as virgin plastic. As a result, manufacturers can save money on production costs, which can be passed on to consumers in the form of lower prices.

Finally, recycled plastic is often stronger and more durable than virgin plastic. This is because it has already been exposed to the elements and has been broken down into smaller particles. As a result, it is less likely to break or crack under pressure. This makes it an ideal material for the production of plastic chairs, which are often subject to heavy use.

In conclusion, the use of recycled plastic in the production of plastic chairs has numerous benefits. It reduces the amount of plastic waste sent to landfills, is often cheaper than virgin plastic, and is stronger and more durable. As such, it is an ideal material for the production of plastic chairs and can help to reduce the environmental impact of plastic chair production.

The Latest Innovations in Plastic Chair Manufacturing

The plastic chair manufacturing industry has seen a number of innovations in recent years. These advances have allowed for the production of chairs that are more durable, comfortable, and aesthetically pleasing than ever before.

One of the most significant innovations in plastic chair manufacturing is the use of injection molding. This process involves injecting molten plastic into a mold to create a chair in a single step. This method is faster and more efficient than traditional methods, and it also allows for greater precision and detail in the finished product.

Another innovation in plastic chair manufacturing is the use of rotational molding. This process involves rotating a mold while heated plastic is poured into it. This method is often used to create chairs with complex shapes and intricate details.

The use of recycled plastic has also become increasingly popular in the plastic chair manufacturing industry. This material is often used to create chairs that are both environmentally friendly and cost-effective.

Finally, the use of 3D printing has become increasingly common in the plastic chair manufacturing industry. This technology allows for the creation of chairs with complex shapes and intricate details. It also allows for the production of chairs in a variety of colors and finishes.

These innovations have allowed for the production of plastic chairs that are more durable, comfortable, and aesthetically pleasing than ever before. As the industry continues to evolve, we can expect to see even more advances in the years to come.

The Role of Quality Control in Plastic Chair Manufacturing

Quality control plays an essential role in the plastic chair manufacturing process. Quality control is the process of ensuring that products meet certain standards of quality before they are released to the market. Quality control is important in plastic chair manufacturing because it ensures that the chairs are safe, durable, and aesthetically pleasing.

Quality control begins with the selection of raw materials. The plastic used to make the chairs must be of the highest quality to ensure that the chairs are strong and durable. The plastic must also be free of contaminants and other impurities. Once the raw materials have been selected, they must be tested to ensure that they meet the required standards.

The next step in the quality control process is the design and production of the chairs. The design must be carefully considered to ensure that the chairs are comfortable and ergonomic. The production process must also be carefully monitored to ensure that the chairs are manufactured to the highest standards.

The final step in the quality control process is the inspection of the finished chairs. The chairs must be inspected for any defects or flaws. If any defects are found, they must be corrected before the chairs are released to the market.

Quality control is essential in plastic chair manufacturing because it ensures that the chairs are safe, durable, and aesthetically pleasing. Quality control also helps to ensure that the chairs meet the required standards and are free of defects. Quality control is an important part of the plastic chair manufacturing process and should not be overlooked.

The Cost of Manufacturing Plastic Chairs

The cost of manufacturing plastic chairs can vary greatly depending on the type of chair, the size, and the complexity of the design. Generally, the cost of producing a plastic chair is determined by the amount of raw materials used, the labor involved in the production process, and the cost of the machinery and equipment used.

Raw materials used in the production of plastic chairs include plastic resins, colorants, additives, and other materials. The cost of these materials can vary depending on the type of plastic used, the quality of the materials, and the quantity purchased. Additionally, the cost of the labor involved in the production process can also vary depending on the complexity of the design and the number of workers needed to complete the job.

The cost of the machinery and equipment used in the production of plastic chairs can also vary depending on the type of machinery and equipment used. For example, injection molding machines are used to create the shape of the chair, while other machines are used to cut, trim, and finish the chair. The cost of these machines can range from a few hundred dollars to several thousand dollars.

In addition to the cost of the raw materials, labor, and machinery, there are also other costs associated with the production of plastic chairs. These costs include shipping and handling fees, packaging costs, and other overhead costs.

Overall, the cost of manufacturing plastic chairs can vary greatly depending on the type of chair, the size, and the complexity of the design. It is important to consider all of the factors mentioned above when determining the cost of producing a plastic chair.

The Future of Plastic Chair Manufacturing

The plastic chair manufacturing industry is an ever-evolving sector that is constantly adapting to the changing needs of consumers. As the industry continues to grow, manufacturers are looking for ways to improve the production process and create more efficient and cost-effective products. In the future, the plastic chair manufacturing industry is likely to focus on the development of new materials, technologies, and processes that will enable them to produce chairs that are more durable, comfortable, and aesthetically pleasing.

One of the most significant changes that is likely to occur in the plastic chair manufacturing industry is the increased use of 3D printing technology. This technology allows manufacturers to create complex designs with intricate details that would otherwise be impossible to achieve with traditional manufacturing methods. 3D printing also allows for the production of chairs with unique shapes and sizes, which can be tailored to meet the specific needs of customers. Additionally, 3D printing technology can reduce the cost of production, as it eliminates the need for expensive molds and tooling.

Another trend that is likely to become more prominent in the plastic chair manufacturing industry is the use of recycled materials. As environmental concerns become more pressing, manufacturers are looking for ways to reduce their carbon footprint and create products that are more sustainable. By using recycled materials, manufacturers can reduce their reliance on virgin materials and create chairs that are more eco-friendly. Additionally, recycled materials can be used to create chairs that are more affordable and cost-effective.

Finally, the plastic chair manufacturing industry is likely to focus on the development of new technologies that will enable them to produce chairs that are more comfortable and ergonomic. By using advanced materials and technologies, manufacturers can create chairs that are designed to provide optimal support and comfort for users. Additionally, manufacturers can use these technologies to create chairs that are more aesthetically pleasing and can be customized to meet the specific needs of customers.

Overall, the plastic chair manufacturing industry is likely to continue to evolve in the coming years. By utilizing new technologies and materials, manufacturers can create chairs that are more durable, comfortable, and aesthetically pleasing. Additionally, the use of recycled materials and 3D printing technology can help reduce the cost of production and create more sustainable products. As the industry continues to grow, manufacturers will be able to create chairs that are tailored to meet the specific needs of customers.

Q&A

1. How are plastic chairs manufactured?

Plastic chairs are typically manufactured using a process called injection molding. This involves melting plastic pellets and injecting them into a mold, which is then cooled and ejected as a finished chair.

2. What type of plastic is used to make plastic chairs?

The most common type of plastic used to make plastic chairs is polypropylene, which is a lightweight, durable, and cost-effective material. Other types of plastic, such as polyethylene and ABS, are also used.

3. What is the process of injection molding?

Injection molding is a process in which molten plastic is injected into a mold at high pressure. The plastic is then cooled and ejected as a finished product.

4. How long does it take to manufacture a plastic chair?

The time it takes to manufacture a plastic chair depends on the size and complexity of the chair, but typically it takes between 10 and 30 seconds.

5. What are the benefits of using plastic chairs?

Plastic chairs are lightweight, durable, and cost-effective. They are also easy to clean and maintain, and they are resistant to corrosion and moisture.

6. Are plastic chairs recyclable?

Yes, most plastic chairs are recyclable. However, it is important to check with your local recycling center to make sure that the type of plastic used in your chair is accepted.

7. Are plastic chairs safe?

Yes, plastic chairs are generally considered safe. However, it is important to check the manufacturer’s instructions to make sure that the chair is suitable for the intended use.

8. How long do plastic chairs last?

The lifespan of a plastic chair depends on the quality of the material and how it is used and maintained. Generally, plastic chairs can last for several years with proper care.

9. Are plastic chairs comfortable?

Yes, plastic chairs can be comfortable depending on the design and the type of material used. Many plastic chairs are designed with ergonomic features to provide comfort and support.

10. Are plastic chairs environmentally friendly?

Yes, plastic chairs are generally considered to be environmentally friendly. They are made from recycled materials and can be recycled again when they are no longer needed.

Conclusion

In conclusion, plastic chairs are manufactured using a variety of processes, including injection molding, rotational molding, and blow molding. Each process has its own advantages and disadvantages, and the choice of which process to use depends on the desired outcome. Plastic chairs are a popular choice for many applications due to their durability, affordability, and versatility.

- what is a plastic chair mat - April 27, 2024

- how much plastic chair in philippines - April 27, 2024

- how plastic chairs are manufactured - April 27, 2024